Bio-sand water filters

Practical Action

The system has proven effective and has become one of the most widely distributed devices

for household water treatment in developing countries.

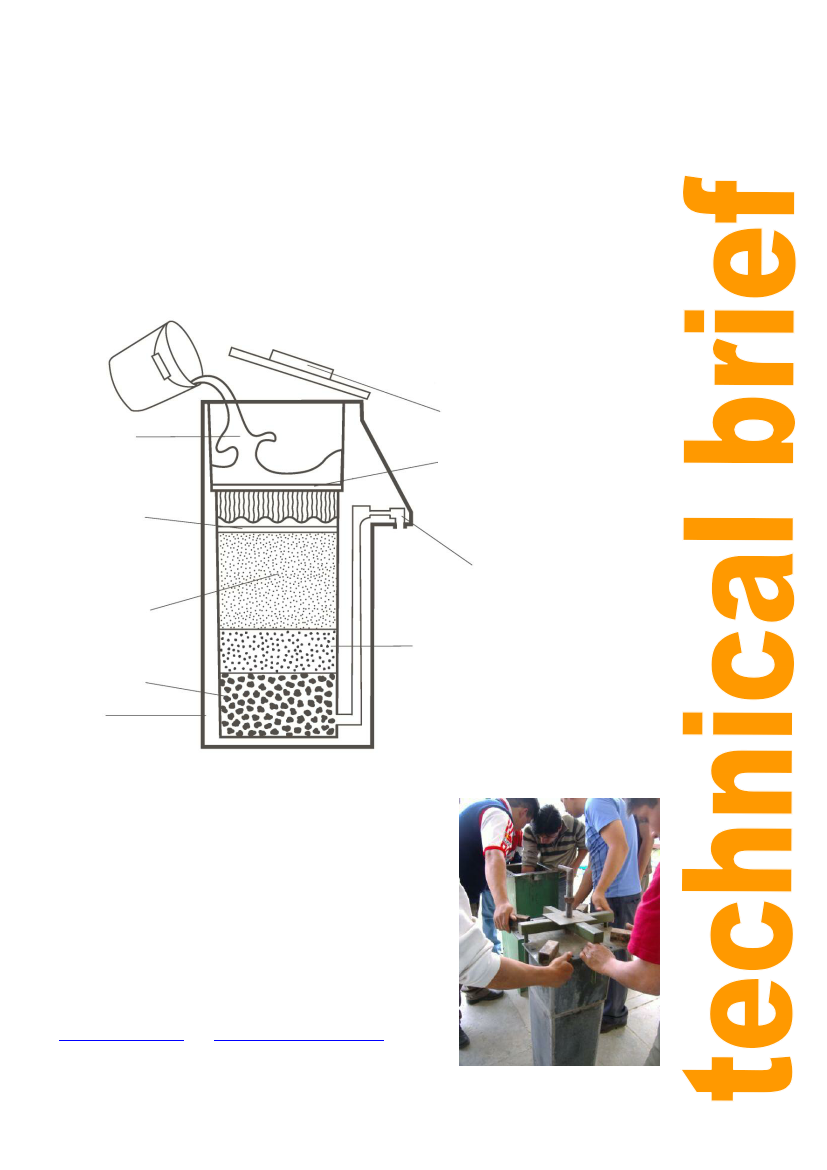

The filter consists of a layer of gravel overlain with prepared sand media contained within a

filter body or box.

The difference in a traditional slow sand filter and the newer bio-sand filter is that the drain is

piped back up to between 1 and 8 cm above the sand level allowing a shallow layer of water to

sit on top of the sand, where the biofilm (schmutzdecke) is created. This ensures that the

sand within the system is always covered by water even when no water is added to the system.

Experimental evidence shows that oxygen will still reach the organisms in the sand.

Contaminated

water in

Wooden

cover

Diffusion

plate

Biologically active

bio-film develops

on the surface of

the sand

Sand

Gravel

Concrete body

cast on site

in shuttering

mould

Outlet pipe

and tap for

clean water

Coarse

sand layer

Figure 3: A typical bio-sand filter cross section. Illustration: Practical Action.

Bio-sand filters can be fabricated locally because they use

common materials. The filter consists of a layer of gravel

overlain with prepared sand media contained within a filter body

or box. One of the initial activities is the selection and

preparation of the sand and the gravel that is used in the bio-

sand filter, this activity is important for the effective and

efficient operation of the filter. Poor selection and preparation

of the sand and the gravel can result in the filter performing

badly and resulting in more work rectifying the problem.

The body is often constructed from concrete using a metal

mould. Construction guidelines are available form

http://www.cawst.org and http://www.biosandfilter.org/.

However, other deigns use oil drums or plastic containers and

2

Figure 4: Removal of the concrete

filter from the metal mould. Photo:

Soluciones Prácticas.